This article, by Dr Brett Glencross, was published in International Aquafeed Magazine in February 2023.

As a kid, I was often schooled by my dad on the value of reusing and repurposing things. My siblings and I used to joke that my dad was the only person we knew who went to the local rubbish dump and came home with more than he took to get rid of. But he is from that post-war, silent generation, that had lots of rationing of things imposed and where they didn’t have the surplus of resources that other subsequent generations have had. So, it was kind of understandable in retrospect. His mentality was one of “there’s no such thing as waste – Just things we haven’t repurposed yet”.

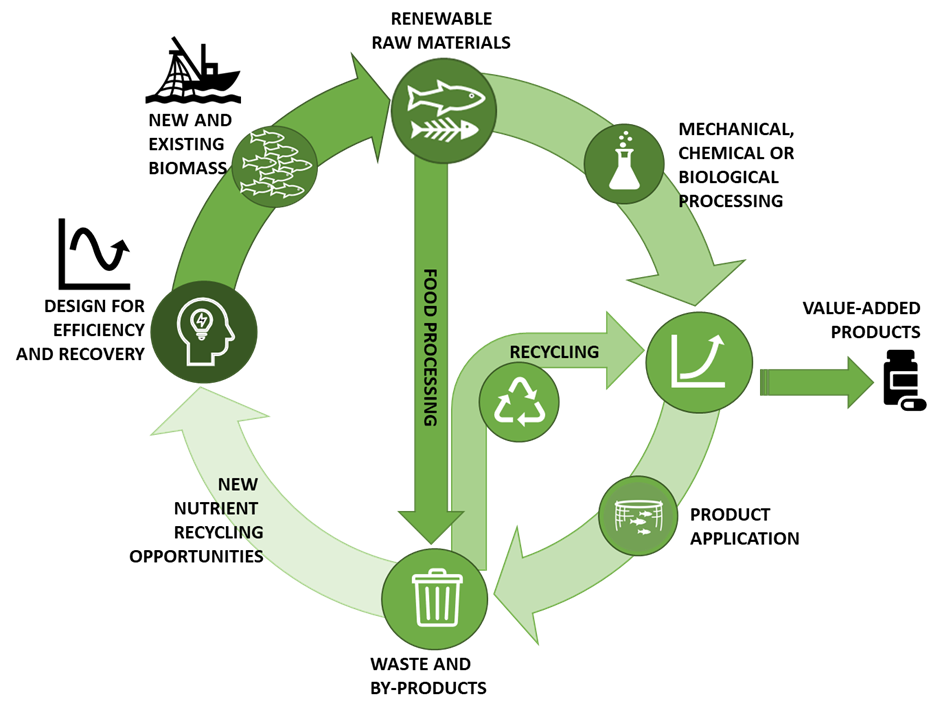

In fact, this mentality seems to be one that is making a resurgence through a range of sectors of late, whether its plastics, batteries, or paper and marine ingredients are another in that regard. While the use of trimmings and by-products is not a new initiative in the marine ingredients sector, the momentum behind the use of these “circular” proteins and lipids is something that is steadily growing. The “new” aspect to this age-old practice is that aquaculture is now a major player in the provision of marine ingredient raw materials, with by-products from farmed salmon, tilapia and pangasius sectors being significant contributors. And we haven’t yet been able to add shrimp into that story yet as the data remain elusive, so the numbers could be much more significant. And when we say significant, we’re talking about 678,000 tonnes of fishmeal being produced in 2021 that came from aquaculture by-products. On the fish oil front, aquaculture is again a major contributor with by-products now contributing more than 30% of all global fishoil production in 2021. While by-products from various pelagic and demersal fisheries remain bigger contributors to marine ingredients (fishmeal + fishoil) production globally, there has been a growing appreciation of circular thinking in how we approach maximum utilisation of whatever resources we have, be they aquaculture or fishery origin (Figure 1). And while this might mean fishmeal and fish oils in some cases, it could also mean value-added products like fish oil for direct human consumption, or hydrolysates or even leather in some cases. The list of value-added opportunities seems to grow each year.

However, we still need to take this thinking further and incorporate it more deeply in our resource use. This means thinking about how we process products, how we manage the by-products to maintain their quality, how we coordinate collection of such by-products to centralise rendering and secondary processing and so on. The use of modern engineering, refrigeration, and logistics systems all come into it. How we best use those products (as feed or food) and being mindful of the regulatory issues surrounding how we process fish and fish products (e.g., fish oils) for human consumption as well. Traceability will also become an issue of growing importance in all this too.

No doubt as aquaculture keeps growing, it will continue to give us a growing resource base from which to make marine ingredients. While the salmon, pangasius and tilapia sectors are doing well here and have in many cases built such circular thinking into their processing, what if we could better facilitate production of marine ingredients beyond those sectors? What about the other millions of tonnes of fish and shellfish whose non-edible parts we don’t use. What more can we do to build a waste-free world? While the FAO announced last year in the State of World Fisheries and Aquaculture (SOFIA) 2022 report that about two thirds of all fisheries are now well managed (about 80% by volume), they also mentioned that the scope for increasing the production from wild-capture fisheries was clearly limited. So clearly from fisheries we need to make better use from what we already have. Again, that comes back to that notion of making sure we achieve 100% utilisation of the resource. As said at the outset, there’s no such thing as waste – just things we haven’t repurposed yet.

Figure 1. Encompassing circular thinking in marine ingredient production. No such thing as waste – Just things we haven’t repurposed yet.