This paper, authored by Dr Brett D. Glencross, was first published in Aquafeed.com in July 2025

Circularity is increasingly core to the marine ingredients industry

There was once a time when nearly all the world’s fishmeal and fish oil supplies were obtained from forage fisheries. These forage fisheries are those that are based on small fish species that have a very limited direct food market, are usually high-abundance, low-trophic-level fish with annual recruitment cycles, and often available only over short peak abundance periods, making steady-state fishery supply challenging. Still to this day, some of those fisheries, like the Peruvian anchoveta and the North Atlantic blue whiting fisheries, are among the largest single-species fisheries on earth. In the 2020s, the use of independent stock assessments, strict fishery quotas and third-party certification systems to substantiate the sustainability credentials of these fisheries has become standard management criteria for most of those stocks. However, it is widely recognized that biologically, we are at the limit of the global supply of such fish species. Therefore, with a finite supply of forage fish, there has been an increasing focus on the use of byproducts to provide the raw material biomass for fishmeal and fish oil production. Today, the use of byproduct waste streams represents one of the best bio-circularity stories around in terms of capturing the full value of animal production/capture in our food chain. In addition to the volume of production from fishery byproducts, increasingly contributing to the story is additional biomass input from byproducts from the aquaculture industry. On the back of this byproduct utilization, global fishmeal production has increased since 2020 from 5.1 million tonnes to 5.4 million tonnes. Notably, this gain surpasses the combined gains from insect, single-cell and algal proteins over the same period. Over the past five years, the volume of byproduct-based production has grown to represent around 1.8 million tonnes (about 35% of total fishmeal production; Fig. 1).

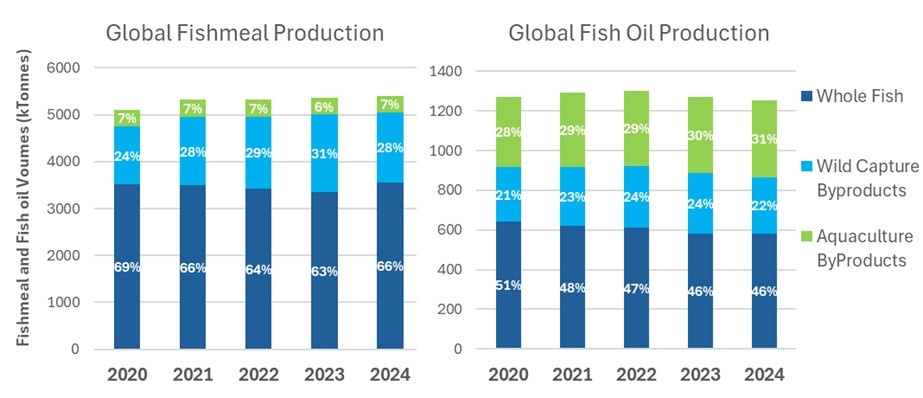

Figure 1. Global fishmeal and fish oil production by raw material input origin from 2020 to 2024.

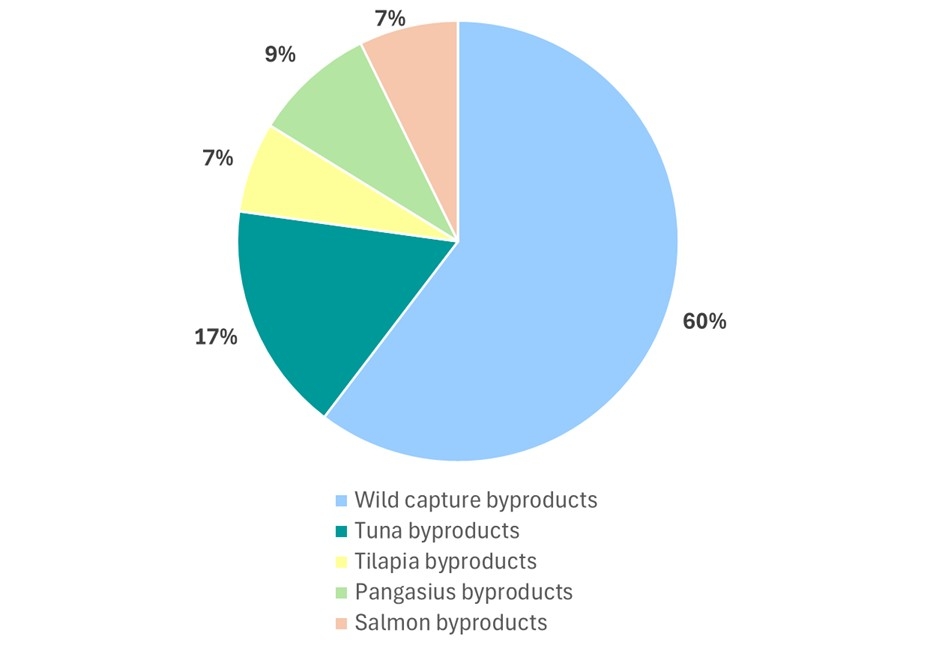

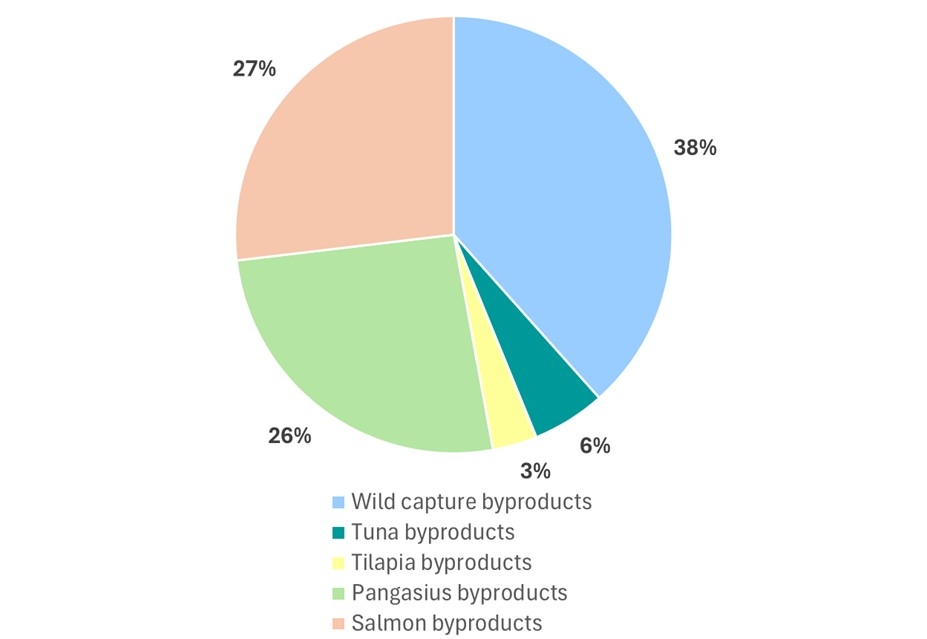

A similar story is seen with byproduct utilization for global fish oil production, which has stabilized over the 2020-2024 period at around 1.2 million tonnes. However, a decline in the use of whole fish resources has been offset by an increase in the use of byproduct resources, to the point where byproducts are now the majority supplier of fish oils. Over the 2020-2024 five-year period, the volume of byproduct fish oils has grown to around 0.67 million tonnes (about 54% of total fishmeal production; Fig. 1). In 2020 it was estimated that 31% of all fishmeals and 49% of all fish oils were from byproducts, and over the ensuring five years this has grown to 35% and 53% respectively (Fig. 1). Combined, that means almost 40% of all fishmeal and fish oil are now being sourced from byproducts in 2024. Within global byproduct utilization, wild capture byproducts still represent most of the raw material supply. Much of this is from demersal species like pollock, cod and hake fisheries, though tuna byproducts are also a major contributor to global fishmeal supply. Aquaculture too is increasingly playing a part in raw material supply, through the use of waste streams like fish frames and trimmings. Progress in this area is also not just an initiative in the developed world, with both the global pangasius and tilapia sectors being major contributors (Fig. 2, 3).

Figure 2 Mean production of global byproduct meals by category in 2020-2023. Data: IFFO, 2024

Figure 3. Mean production of global byproduct oils by category in 2020-2023. Data: IFFO, 2024

Although there is improvement in the management of global fisheries throughout the world, there is still much work to be done, and things are still far from as good as they should be. Cuts to total allowable catches (TACs) in the early 2000s are now reaping benefits in terms of stabilizing fishery biomasses in many of the large forage fisheries around the world. The increased use of third-party sustainability certification systems, like MarinTrust, RFM, ASC and MSC, and the associated market forces are being used to drive responsible resource use across the sector. Despite these positive signs it is unlikely that we will see total forage fishery catch exceed much more than 16 million tonnes a year into the future. This means that fishmeal and fish oil yields from that resource are constrained to about 4 million tonnes a year (assuming a meal yield of 22% and oil yield of 3%). Many of those same improvements applied to forage fisheries are being extended into other large DHC fisheries in the developed world. This means that with improvements in fishery sustainability for DHC, we will also be improving our biomass base for the production of byproduct based fishmeal and oils. Based on FAO estimates for fishery yields in 2050 of 80 million tonnes, it has been suggested that of the 64 million tonnes that are predicted to be caught for DHC, we should be able repurpose up to 33% of that biomass as byproducts (~20 million tonnes) to produce another 5 million tonnes of fishmeal and oil. We are presently processing almost 7 million tonnes of biomass (~1.8 million tonnes of fishmeal and oil), meaning that we are only repurposing about one-third of this valuable resource. Aquaculture is another part of this story, with unprecedented growth seen in this food production sector over the past twenty years and predictions are for this to continue. The FAO estimates that aquaculture production by 2050 could see production reach 140 million tonnes. Even if we take a conservative view of only being able to repurpose up to 15% of that biomass as byproducts (~20 million tonnes) by 2050, then that would contribute another 5 million tonnes of fishmeal and oil. Presently, in 2020, we already repurpose about 3 million tonnes of aquaculture byproducts and there is still much more that could be done to improve the supply and use of those products. However, it is certain that so long as we keep fishing and growing fish in aquaculture for human food, then we will always have fishmeal and fish oil available as strategic feed resources by using the associated byproducts.

Still the global nutritional benchmark

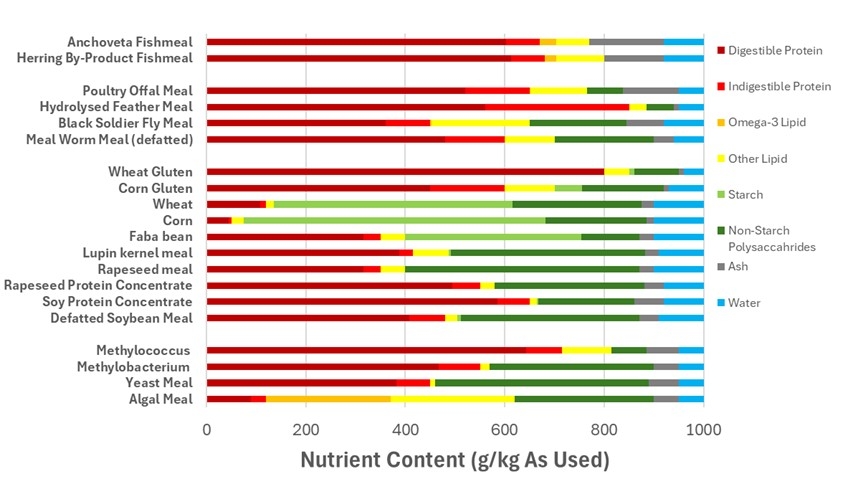

With the growth of global aquaculture, there has also been a dramatic rise in the use of aquafeeds, reaching over 50 million tonnes in 2020. At that time, global marine ingredient use in aquafeeds was less than 5 million tonnes (fishmeal + fish oil), meaning that more than 45 million tonnes of feed materials other than marine ingredients made up the bulk of that supply. One of the shining success stories of aquaculture has been its capability to adapt to and use grain products like soybean and wheat, which have been the dominant resources supplying those nutrients over recent decades. The development of that story was covered in a FAO thematic paper published in 2023 about how a global effort of “harvesting the benefits of nutritional research to address global challenges in the 21st century” was applied to underpin that transition. That being said, the development and assessment of the various feed resources that we examined was undertaken using fishmeal and fish oil as the nutritional benchmarks, and for good reason; they represent an almost ideal nutritional option for most aquaculture species. Not only do they have highly favorable nutrient profiles (Fig. 4, 5) compared to many of the alternative ingredients, but they also present favorable nutritional characteristics of digestibility (Fig. 6) and palatability (Fig. 7) compared to them as well.

Figure 4. Typical composition of a range of common protein feed resources used in aquaculture feeds. Figure from Kumar et al. (2025)

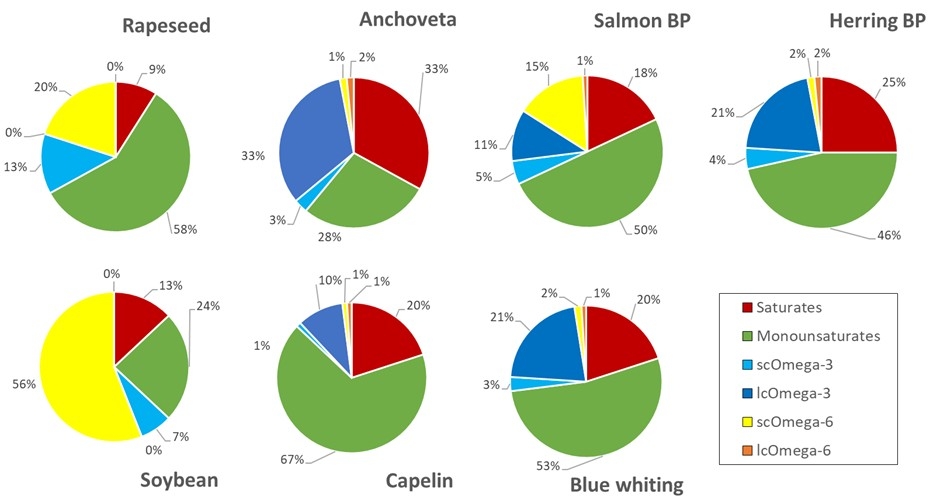

Figure 5. Fatty acid profiles of various oils. Shown are the profiles for rapeseed and soybean vegetable oils, along with salmon by-product and herring by-product oils. Whole fish oils from anchoveta, blue whiting and capelin are also included. Shown are the fatty acid classes of saturates, monounsaturates, short-chain omega-3 polyunsaturates (scOmega-3), long-chain omega-3 polyunsaturates (lcOmega-3), short-chain omega-6 polyunsaturates (scOmega-6), and long-chain omega-6 polyunsaturates (lcOmega-6).

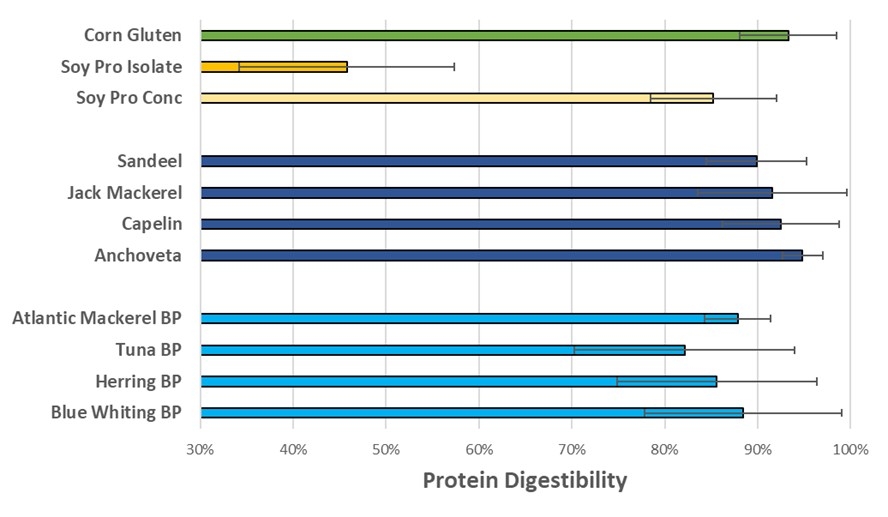

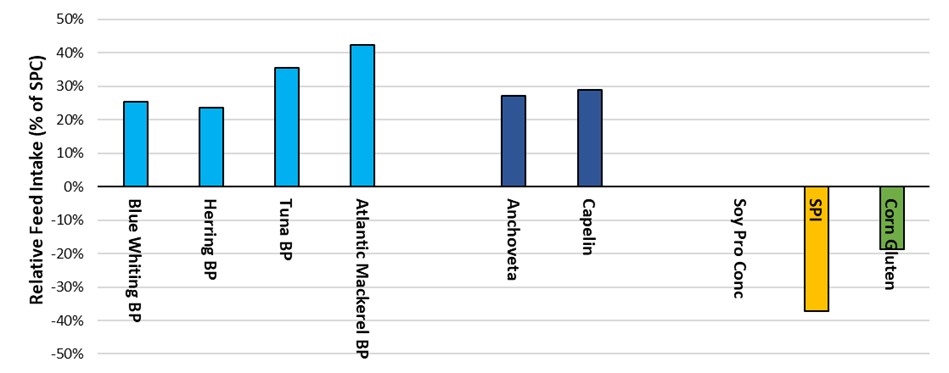

This raises one of the criticisms of byproduct fishmeal and fish oils, in that they are seen as second-rate compared to other resources. While this may have been the case in the past, recent evidence does not support this with modern fishmeal and fish oils. There is a growing volume of work showing that both fishmeal and fish oil from byproducts can be produced to high-quality specifications, though admittedly the byproduct fish oils are usually lower in EPA and DHA than high grade fish oils like anchoveta oil but can be similar in lc-Omega-3 content to other oils like capelin or blue whiting oils. Much of the improvement in quality has come from adopting modern processing technologies using low temperature drying and ensuring the maintenance of cold-chain management systems for the raw material. This later step, critical to ensure biogenic amine production, is kept down prior to processing and avert any spoilage of the valuable biomass prior to processing. Work undertaken by IFFO comparing the quality of various byproduct fishmeal against several other fishmeal and grain product ingredients shows that both their digestibility and palatability criteria can be equally as good as many of those other resources (Fig. 6, 7). Feed ingredients often bring features beyond their primary nutrition contributions. In some cases, this might be the introduction of negative elements like antinutritional factors (ANF) that many plant ingredients bring, or it can be positive like feed palatability enhancing properties that many marine ingredients bring. For the most part, palatability is managed by feed formulators through their “art” in terms of knowledge of which ingredients possess positive, negative or neutral impacts on the palatability story. However, it is an increasingly important area in feed ingredient research as the increasing use of plant proteins has led to diets with often a neutral and sometimes negative palatability characteristics that need to be managed through the inclusion of palatants like hydrolysates. The use of hydrolysates, often also made from marine resources, has been a growing part of the aquaculture feed sector over recent decades, with various companies now producing a wide range of products from both wild-caught and byproduct resources. Notably, the different resources often result in markedly different characteristics of those products, which provides substantial flexibility in product choice, but there are also significant differences in responses to products based on hydrolysate type, inclusion and raw material base.

Figure 6. In vivo (Atlantic salmon) protein digestibility of a selection of by-product fishmeals, whole fish fishmeals and several plant protein ingredients. Data IFFO (2025).

Figure 7. Relative feed intake by Atlantic salmon of a standard commercial reference diet formulation where the test diets had a 30% inclusion of the test ingredient. Included as test ingredients are a selection of by-product fishmeals, two whole fish fishmeals and several plant protein ingredients. Data is presented based on the relative feed intake response compared to the soy protein concentrate (Soy Pro Conc) diet, as this ingredient represents a well-known, consistent, highly reproducible commodity. Data IFFO (2021). Notable is that all fishmeals result in a clear improvement in feed intake, while each of the plant ingredients has the opposite effect.

Feed ingredients often bring features beyond their primary nutrition contributions. In some cases, this might be the introduction of negative elements like antinutritional factors (ANF) that many plant ingredients bring, or it can be positives like feed palatability enhancing properties that many marine ingredients bring. For the most part, palatability is managed by feed formulators through their “art” in terms of knowledge of which ingredients possess positive, negative or neutral impacts on the palatability story. However, it is an increasingly important area in feed ingredient research as the increasing use of plant proteins has led to diets with often a neutral and sometimes negative palatability characteristics that need to be managed through the inclusion of palatants like hydrolysates. The use of hydrolysates, often also made from marine resources, has been a growing part of the aquaculture feed sector over recent decades with various companies now producing a wide range of products from both wild caught and by-product resources. Notably, the different resources often result in markedly different characteristics of those products, which provides substantial flexibility in product choice, but there are also significant differences in responses to products based on hydrolysate type, inclusion and raw material base.

Now also the sustainability benchmark

The sustainability of marine ingredients in aquafeeds has also been a focus for many years. There are various measures (metrics), like FIFO and FFDR that have been applied to assessing sustainability and each of those comes with its own range of assumptions and is only as good as the reliability of the data feeding into them. A recent review presented the background behind each of these metrics, aspects of their origins, and each of their shortcomings was examined. A key failing of many of those metrics, though, was that none of them allowed for the assessment of “trade-offs” and the consequences thereof; that is the passing of risk from one resource to another. Using a feed metric that focuses solely on marine ingredients, without recognizing that replacing these ingredients with an alternative does not necessarily improve sustainability, reduce risk, or even change the global impact on fisheries, does not really help improve the sustainability of the feed. What is really needed is a holistic assessment, something that includes all aquaculture feed ingredients in a common metric. And the reality is we already have that, and it is called life cycle assessment (LCA). By promoting such a shift in feed sustainability thinking towards LCA, we move towards a more transparent assessment process, which will better support aquaculture to move forward by being able to assess the sustainability of the use of all feed ingredient resources on a shared assessment framework. When examined using an LCA framework, we increasingly observe that marine ingredients perform better than most other feed ingredients on a wide range of indicators like carbon footprint, land use, water use and so on. The use of byproducts as the raw material input into this further improves those sustainability indicators. As such, increasingly marine ingredients have moved from being a nutritional benchmark to also being a sustainability benchmark.